The Process – Then and Now

From the early days of converted desktop inkjet paper printers to today’s purpose built DTG

machines, many things have changed, but the process has remained virtually the same. 100% cotton

shirts are still the best substrate. We’re still printing water base ink through an inkjet print head. And we’re

still applying pretreat solution to the shirt prior to printing white ink.

Some of the key changes and developments:

- Better pretreat solutions

- Better application methods for pretreat

- Improved print head technology

- Better ink chemistry

- Faster production speeds

- Availability of pre-pretreated shirts

- The use of conveyor dryers for curing

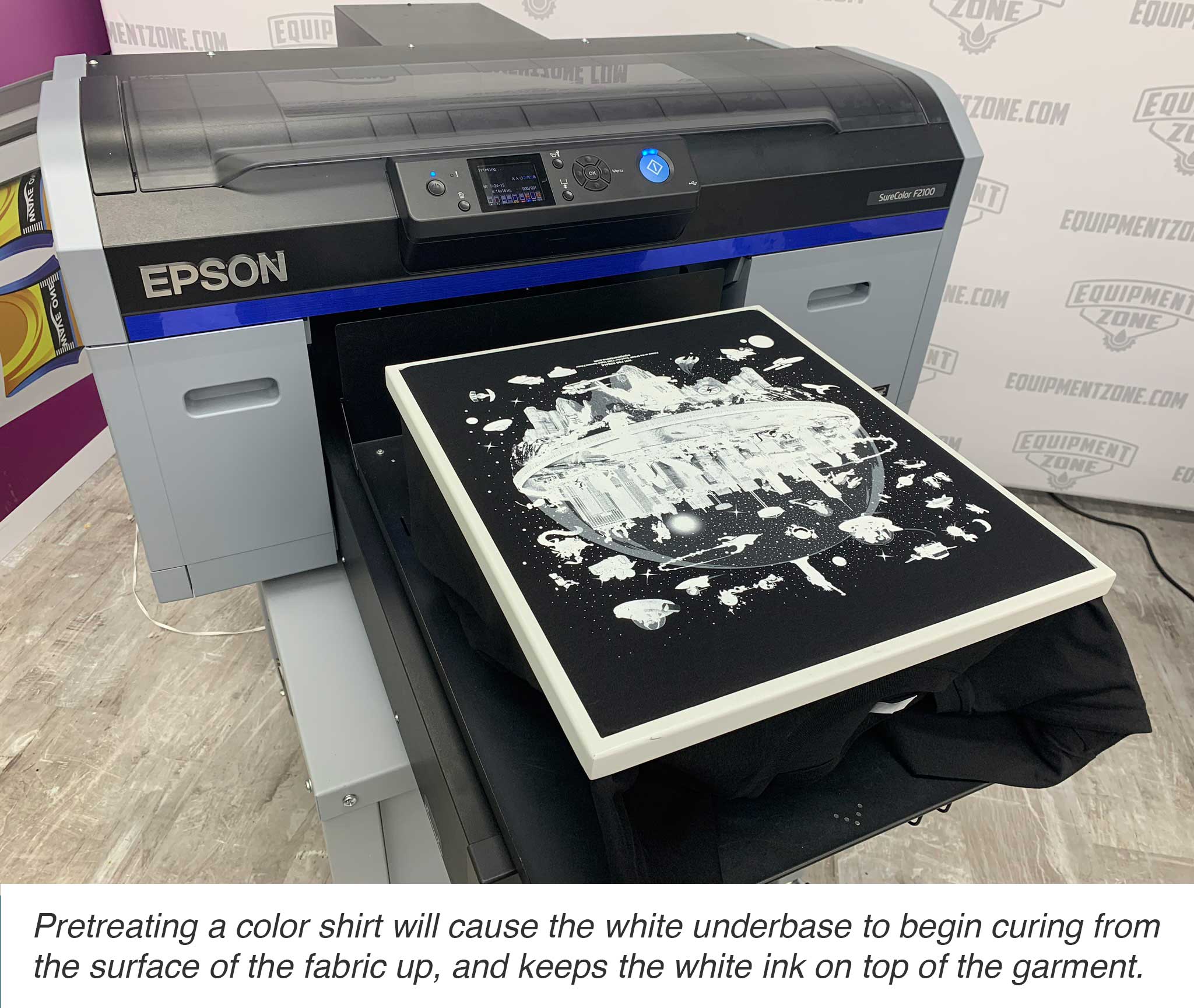

Pretreat solution has progressed over recent years from a stiff and sometimes yellow chemical on the garment to a thinner, more clear solution. Pretreat solutions are available for color shirts (white uderbase) and white and light color shirts (no white ink). The purpose of pretreat is to cause the ink to begin curing on the shirt surface before it can absorb into the fabric. This is similar to the way a screen printer will print a white underbase and flash the ink before applying the other colors. Pretreat causes the ink to “flash” on the surface of the garment.

You can pretreat a white or pastel shirt when printing CMYK inks only, but it’s not required. Pretreating these garments will give you a brighter, more crisp image, and better washability.

Most DTG decorators today see an automatic pretreat machine just as important as the printer and a heat press or conveyor dryer. The majority of decorators today have forsaken the pump bottle, the paint roller, and the power sprayer for an automatic pretreat machine. Uniformity of application, not to mention cleanliness, is the primary reason.

Pretreating shirts with any method that gives inconsistent laydown of product to the surface of the fabric will result in inconsistent prints. In other words, the amount of pretreat, and the consistency across the entire image area will impact the finished print.

Early print heads used in the DTG process were built for printing on paper, and for a different ink chemistry as well. This was the cause of some clogging issues, and is still an issue today with machines that are still manufactured as repurposed paper printers. But there are machines today with print heads specifically built for use with DTG water base textile inks.

Developments in inks, most specifically in white inks, have improved reliability of these printers. The titanium dioxide used as a pigment in white ink today is better suspended in the ink resulting in less settling of the solids, and therefore less print head clogging as a result.

Faster production times are making DTG printing more competitive with other decoration methods in the marketplace. The use of multiple printers to increase productivity is becoming much for common as well.

Purchasing garments that come pretreated already is becoming more common and available. In the not so distant past, these shirts did not print well, but today they print just as if you pretreated the shirt yourself.

Heat presses were for many years the norm when it came to curing DTG printed garments, and the majority of decorators still use heat presses for curing. But conveyor dryers are becoming more and more popular with decorators, especially if you have more than one DTG printer. Once a decorator adds a fourth or fifth printer, it’s common to also upgrade to a conveyor dryer as well.

What’s Next?

Speed, speed, speed is next on the horizon. We’ve gone from shirts taking 10 minutes or more to print in the early days, to shirts being printed in under a minute. The average print time for a 10”x12” image on a color shirt today is still around two minutes, and a white shirt in less than a minute on even the least expensive printers.

Purchasing pretreated garments will only increase with more availability from garment manufacturers. Will pretreating your own garments completely go away? Probably not, since our customers sometimes dictate which garments they want you to decorate. And unique styles and colors (Texas Orange, North Carolina Blue) will require us to at least have the capability to pretreat garments outside of the offerings from manufacturers.

Hybrid DTG Printing

Combining screen printing and DTG printing has been a dream since the first days of DTG development. Today this is becoming more of a reality. One very recent innovation has been the introduction of printing with plastisol inks on the screen press before application of the DTG print. In the past, only water base inks were effective in this hybrid process.

The craft of full color, photographic images laid down using screens may be disappearing. While many screen print decorators can produce beautiful photographic images on color garments, developments in DTG decorating in combination with screen printing may make this technology obsolete.

What to Consider Starting or Adding DTG

For nearly all garment decorators, we’re living and working in a new world. A world where the consumer wants it custom, wants one, and wants it now! Even professional buyers are approaching their garment decorators and asking for multiple shorter runs rather than larger production runs. Professional buyers today, more and more, do not want to carry large inventories of decorated apparel, but want you to become more of their warehouse of goods. That means for some of these customers, you will need the ability to produce in a more on-demand environment.

Here are a few checkpoints in your decision to add DTG to your decoration options:

- Leaving money on the table by turning away shorter run work

- Looking to have an online ecommerce presence

- Working with a less skilled labor pool since the training is much less complex

In the early days of DTG, screen printers were wary of this new technology. But after watching this new decoration method, many screen printers came to the realization of just how many orders they turned away due to minimums.

Despite the newness of DTG decoration, it is unusual today for an online garment reseller to not be using this technique. Your inventory is blank goods, and orders are filled on demand, many times printing and shipping the order the day it is received.

While a learning curve does exist in becoming an expert DTG decorator, that window is much smaller than most any other kind of decoration method. Unlike screen printing for example, with a variety of screen mesh counts, ink options, etc., DTG printing is basically repeating the same steps over and over again. In fact, most of the printing decisions are made in the art department. A machine operator will generally only load and unload the garments.

For more decorators, if it hasn’t already happened, DTG is likely in your future. With advances in inks, pretreats, and machines, this transition is becoming a much easier decision to make.

About the Author

Terry Combs is a 40+ year veteran of the garment printing industry, and has managed production shops large and small across the United States. He has written hundreds of management and technical articles for garment printing publications and spoken at industry events worldwide. He is currently in DTG sales and training with Equipment Zone.